STEM in the fast lane – the car design project that teaches students to think like engineers

Tim Brotherhood recalls how an ambitious STEM project involving Scalextric cars was a great success in its day, and is now ripe for a revival, given schools’ access to modern edtech…

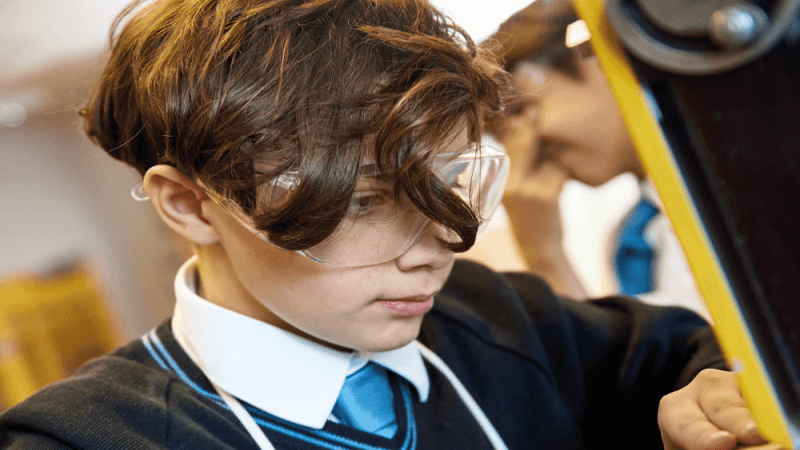

As the pupils gather in the digital design and manufacturing studio after school, there’s a buzz of excitement in the air.

At the last session, they tested out the performance of their Scalextric cars on a tight and twisty test track. After some exciting races, they recorded a wide range of parameters for each car, including the motor position and layout, gearing, key dimensions, lap times, and how each car coped with the track’s layout.

Today, the pupils will be using the data captured at that previous session to inform what will be their first design. At the same time, they’ll be needing to ensure throughout that their designs comply with a set of competition rules that they’ve been studying at home.

Designing in 3D

Students Tony and Alice open a web browser and log into Onshape – an online CAD platform that’s free to access for schools. Tony proceeds to open the starter assembly from their team’s digital workspace, before choosing the preferred motor layout and changing the design’s dimensions according to the measurements of the track, wheelbase, and slot guide position. The assembly updates in seconds, allowing him to then start creating the chassis of what will be their car.

Alice then opens the same assembly on her phone, seeing instantly the design elements Tony has configured, and begins modelling the car body that will enclose the components in a strong, light and streamlined shape.

Elsewhere in the group, Rhi is busy using graphic design software to produce information packs aimed at generating interest among local businesses in sponsoring her team. Once the sponsors are finalised, Rhi will set about designing graphics for team’s uniforms, as well as transfers containing logos and other graphics for the car, once its shape and design is finalised.

Nicole and Tom, meanwhile, are planning out the digital manufacture of their car with the aid of a virtual workpiece, which will be machined on a computer-controlled router in order to form the mould they’ll use to vacuum-form the car’s body.

Having researched the mechanical properties and sustainability characteristics of Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA) polymers, Tom now loads PLA into the 3D printer, ready to purge the previous material.

His first print will aim to test that everything’s working properly, while also producing standard shapes that his team can use for impact and tensile strength tests. As the weeks go on, the students carefully follow and iterate upon their designs, testing as they go, in an effort to improve their car’s performance at each stage.

The above describes a typical scene in schools that have opted to run the Scalextric4Schools Challenge (S4S) as an after-school STEM club project.

Applied knowledge

S4S was borne out of a KS3 project originally developed by Edgecliff High School in Staffordshire in partnership with Hornby, commercial owner of the Scalextric brand. Brokered by the 3D modelling software supplier PTC, S4S was first launched in 2009 as both a KS3 learning project and an inter-school competition.

Hornby’s contribution included giving students access to its designers and engineers, examples of commercial slot car designs and supplying cost-price components and track, as well as various competition circuits and prizes.

Students taking part in S4S got to design, make and race their own slot cars, following the same processes used by professional product designers and engineers. The project called on students to demonstrate a scientific understanding of materials, control systems and motion, and apply their knowledge to the development of fast and efficient racing cars. Students also had to apply maths skills to quantify their car’s virtual performance and physical motion on the track.

Trending

The result of all this testing then guided the students as they sought to improve their designs over a number of iterations – while also having plenty of fun, racing the cars they had created against each other.

I was working for PTC at the time, and helped develop the rules for the competition while also authoring accompanying guides to the software, design and manufacturing processes involved. The S4S Challenge ran for several years, with the finals eventually finding a home at the Royal Air Force Museum Cosford. Teams from across England and Scotland took part initially, later with schools from Russia also taking part. Spin-off challenges were latterly run in Australia and Dubai.

Sadly, 2014 was the last year in which I worked for PTC, and the final year in which the competition was held in its original form. Fast forward to late 2021, and a Facebook group set up around the original challenge initiative suddenly burst into life. By Christmas 2021 it had attracted hundreds of new members – albeit mostly D&T teachers. The original curriculum guides can now be found there, alongside a wealth of new resources submitted by others and some lively discussions.

Virtual testing

With schools now routinely using externally produced resources to support their lessons, there are fewer barriers than ever for teachers who are keen on helping their students to tackle ambitious design challenges.

As can be seen by our previous success with S4S and the continued interest in the project, schools have it in their power to offer their students rich, yet highly cost effective STEM learning experiences.

PTC’s Onshape remains available in a free, browser-based version accessible by schools on almost any digital device, including mobiles. With no software installation required, classes don’t even have to run the security gauntlet of their school’s computer networks.

Moreover, many more schools now possess the kind of desktop manufacturing equipment – such as CNC routers and 3D printers – needed for projects like S4S to be properly realised. When taught well, D&T can offer pupils highly engaging and memorable STEM experiences – not ones based on single-subject tasks, but far-reaching, multidisciplinary projects that are relevant to their interests and suitably challenging.

Technological advances since the initial run of S4S challenges mean that students can now use analysis software to test the performance of their virtual designs in simulated wind tunnels; explore the heat build-up in small electric motors; use kinematic and dynamic motion simulation to measure gearing, acceleration and cornering; and Finite element analysis to identify areas where chassis material can be removed without compromising strength.

This virtual testing can result in even greater improvements before committing to physical manufacture, further testing and improvement – the very same processes that design and engineering professionals will follow every day.

Tim Brotherhood is a STEM ambassador and former head of D&T, now working as an education programme manager for a global software company