D&T – Use this exercise to teach the importance of precision in manufacturing

Would pupils want to get on a plane powered by engines manufactured to tolerances of 0.01mm or 15mm? This simple activity will teach them the importance of getting things exactly right, says Joanna Chidgey…

Technical concepts such as precision measuring, working tolerances and interference fit are part of most design and make tasks. This short exercise utilising CAD/CAM can be built into many D&T activities.

The manufacture of an interlocking ‘X’ covers the environmental advantages of fabrication without adhesives or mechanical fittings.

Even better, it addresses the perennial problem of what to do with those tubs of acrylic offcuts that seemingly refill themselves overnight.

A speedy hands-on exploration of interlocking toy dinosaurs precedes a discussion on the importance of tolerance.

Pose the following question: ‘Would you want to get on a plane powered by engines manufactured to tolerances of 0.01mm or 15mm?’

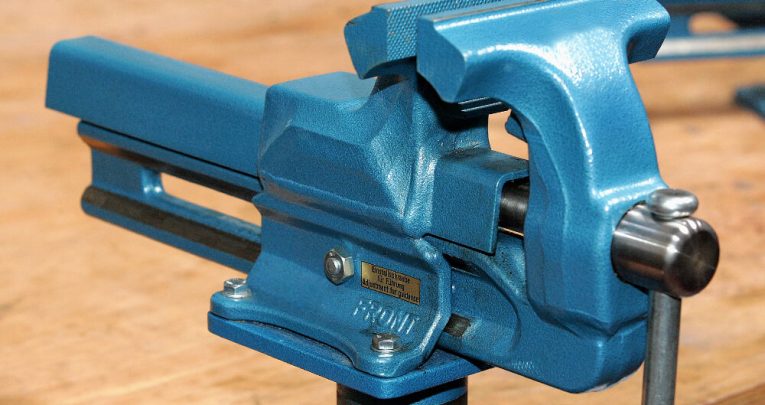

A nice, chunky coach bolt with an overly large nut will illustrate the point.

We then consider how acrylic sheets are manufactured within tolerance and sold as 3mm thick, despite often ranging between 2.8mm and 3.2mm. Not much – but it is if you’re trying to manufacture with precision.

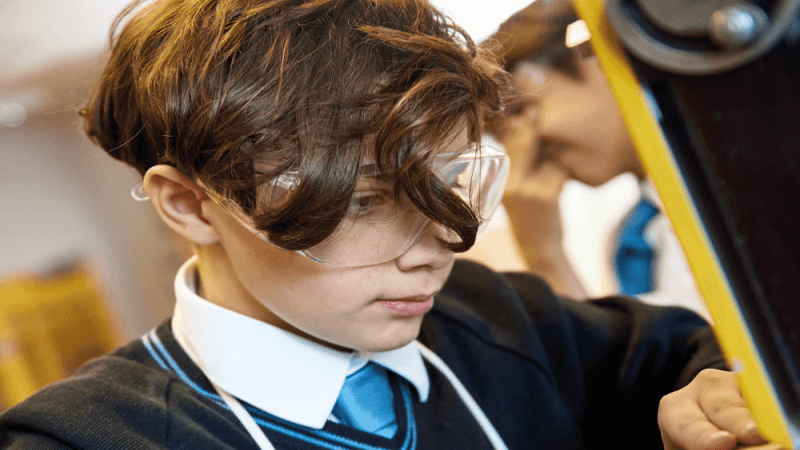

Working in pairs, the students use Vernier Calipers to measure samples held steady in vices and compare their results. Invariably, few sheets will measure 3mm exactly.

Their faux indignation at this affront to their consumer rights will amuse, but the underlying point is that we should always check and measure precisely to ensure accuracy.

Trending

Taking an offcut of their acrylic, the students proceed to measure the thickness accurately.

Using 2D Design CAD, they then draw two identical 50 x 50mm squares, each with a slot to receive the thickness of their corresponding piece.

This may be drawn using grid spacing or the line length function, before being cut on the laser cutter.

There will be a palpable air of competitive anticipation by this point, as I’ll usually have offered a motivational bribe for the best ones.

Samples that fall apart are met with rueful groans, while those emitting that elusive first-time ‘click’ are met with resounding cheers and fist-pumping…

Joanna Chidgey is head of product design at a secondary school in London.