30 Second Briefing

30 Second BriefingThe world’s first desktop waterjet cutter, the Wazer is compact, affordable, and capable of cutting almost any material. Bringing advanced engineering technology to the classroom, the machine is exclusively available to education from approved supplier, Denford.

Here, Steve Oddy, managing director of Denford, talks through just five of the fantastic benefits the Wazer brings to schools, colleges and universities…

1. Cut (almost) any material

There’s no other machine that cuts as wide a variety of materials as a waterjet cutter, so the Wazer brings an incredible amount of manufacturing freedom to schools.

Capable of cutting everything from stone, glass, plastic, metal, carbon fibre, and composites to softer materials such as rubber and foam, the machine expands the range of materials that a typical laser or router can accommodate.

In terms of technical specifications, the Wazer can cut stainless steel to 4.5mm, mild steel to 6mm, carbon fibre to 6mm, porcelain to 9mm, aluminium to 12mm, and glass to 19mm.

The flexibility this provides means that teachers and students are almost entirely unrestricted when it comes to project work.

2. Bring industry capability to the classroom

The Wazer is truly a revolution. Until now, waterjet cutting machines were reserved exclusively for large-scale manufacturers due to their power and size.

The Wazer has brought this industrial capability to the classroom, meeting schools’ requirements from both a space and budgetary perspective: it fits with ease inside classrooms, and prices start from just £7,999.

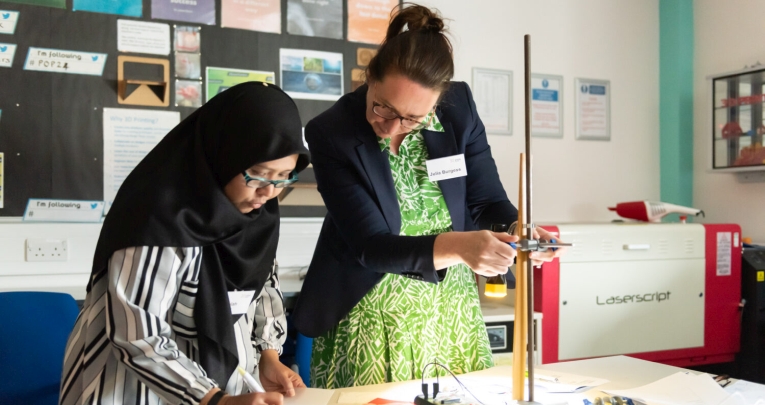

3. Teach students key skills

Equipping pupils with the real-world knowledge and skills they need to progress in the modern workplace, the Wazer is invaluable in setting students on the path to successful careers in everything from product design to mechanical engineering.

Pupils are able to use their existing CAD (computer-aided design) software to create DXF files (a type of vector), while the Wazer’s own CAM (computer-aided machining) software, WAM, makes creating cut paths simple – the CNC (computer-numerical-controlled) program is simply transferred by SD card to be cut by the Wazer.

4. Ease of use

User-friendly by design, the Wazer is a machine that students and teachers alike love to use.

A step-by-step process guide teaches everything from how to install through to how to cut, and each element has been developed for speed and ease – while its fast-clean nature means that there is minimal set-up and shutdown time required, so class after class can be up and running within minutes.

5. Get creative

Our young people have truly astounding ideas, and so much of what they can conceive is hampered by the tools they have access to. The Wazer unleashes the potential of our future innovators by providing them with the ability to make the most creative of concepts a physical reality.

- Cuts both hard and soft materials

- Compact in size, fits in any classroom

- Teaches students real-world engineering skills

- Easy-to-use software and interface

- Simple workpiece clamping

- Easy-to-set datum and relocate cut file

To request a free sample of a Wazer-cut product, email info@denford.co.uk or call 01484 728 000. You can learn more online here.